Introducing the Food Science Series, through these articles, we will explore different aspects of food science as well as the people investigating within these fields.

Water, barley, hops, and yeast, the quadfecta necessary for brewing of beer, one of the most important food inventions of the human civilization in over 5000 years (Curry, Andrew, 2017). However, despite the long history, our understanding of how yeast and water combine with the proteins and carbohydrates found in barley can produce the various textures and flavors to the beverage as we know it today is still limited. In this episode, we will explore a little bit of science that is currently being used for studying the connection between these elements with a colleague of ours, Mr. Edward Kerr, a current PhD candidate at the School of Chemistry and Molecular Bioscience (SCMB), The University of Queensland (UQ).

What is your work? What do you do? And what is the scope of your project?

I’m doing a PhD in Biochemistry, focusing on brewing biochemistry. I use proteomics and metabolomics to understand and optimise the brewing process. My project also involves using microbiology techniques to isolate and characterise wild yeast from Brisbane for beer brewing.

Beer yeast or Saccharomyces cerevisiae was originally described in 1838 by Dr. Franz Julius Ferdinand Meyen (Meyen, 1839). S. cerevisiae has been isolated and developed specifically for their ability to convert sugar from barley into alcohol for beer production. Contamination with other yeast strains in commercial production often corrupts the process and the expected taste and texture profile of the beer. Specific brewing apparatuses have been used by the industry to minimize contamination from wild yeast in the environment since 1886 (Stewart, 2017). Nonetheless, when the aim is to achieve new flavor profiles for beer production, more often than not, wild yeast strains are used alongside traditional and non-traditional brewing components.

For this project, Ed has approached a local brewery. The Newstead Brewery, located in Brisbane, Queensland, Australia, for a collaboration for collecting and characterizing wild yeasts for production of beer. The specific aim is to produce more interesting flavors as well as demonstrating the complexity of brewing when wild yeast from the environment. The knowledge gained from the adaptation as well as optimization of the commercial brewing process for wild yeast could have potential for changes as well as improvements in the current brewing process, that uses domesticated yeast, for better beer production.

What is proteomics? How is it used in your project? And How often is it used in the beer industry?

Proteomics is the study of the proteome, which is an entire set of expressed proteins within a system. We use proteomes to identify and measure the changes in protein abundance throughout the brewing process. The brewing process is based on malted 1Malting is the germination process where digestion enzymes are released by the grain to convert complex carbohydrates into simpler forms. barley seeds and yeast, therefore barley and yeast proteins that are present and change throughout the process. The change in the proteome throughout the brewing process can affect the final product. With different proteins having different effects on beer and taste. Proteomics has been used previously in the brewing field, most research that has used proteomics relies on older techniques.

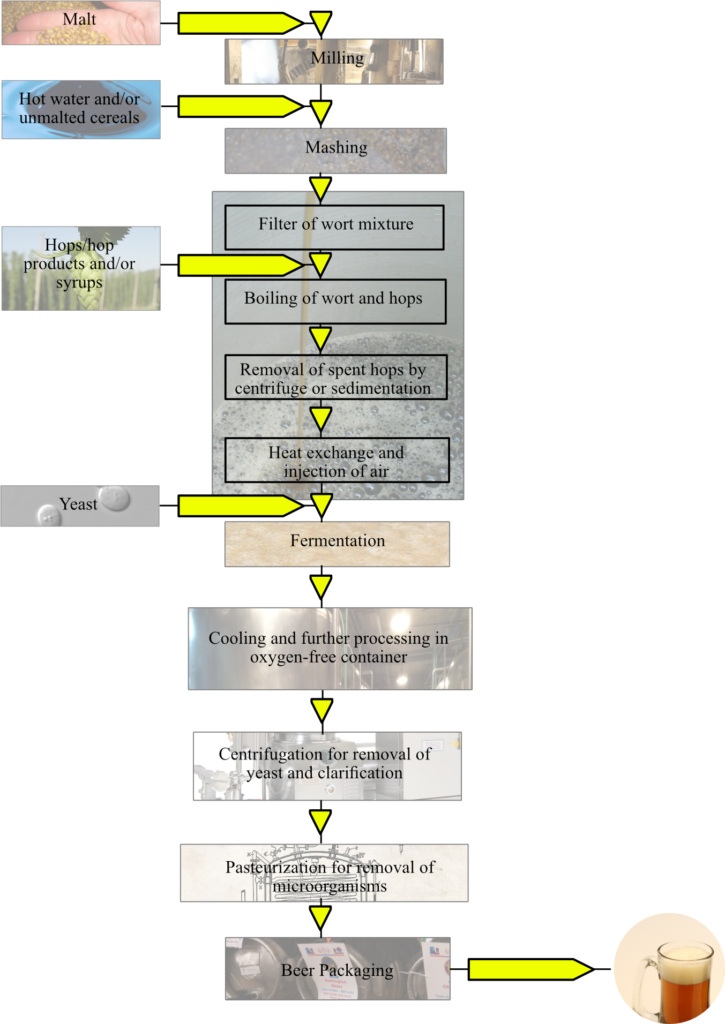

The traditional brewing process includes the breaking down of complex carbohydrates into a yeast-compatible food resource within a solution (Willaert, 2006). This mixture is called the wort. Yeast fermentation process would convert the available nutrient to alcohol and other flavoring byproducts (Willaert, 2006). Using a proteomic technique such as mass spectrometry on samples collected during the process, it is possible to follow and identify the changes within the proteome of the mixture through each step in each sample.

Current proteomic processes are not utilized in large scale beer manufacturing due to its cost. Manufacturers right now are only looking at what is there, and not at what are the specific differences or changes during the beer process. In a previous study, Ed utilized proteomics for the investigation of the proteome changes from the beer brewing mashing 2Mashing is the process to dissolve sugars and proteins from the grain into a solution. process (Kerr, Caboche, & Schulz, 2019). The result of this study showed that early in the mashing process some of the protein population within the solution, are cut up by barley proteases (Kerr et al., 2019). These protein fragments are vulnerable to the high temperatures used during the mashing process and precipitated (Kerr et al., 2019). This further demonstrated the complexity of brewing, where the protein solubility that affects the flavor profile can in turn be affected by various factors ranging from brewing parameters to the specific characteristics of the different barley varieties (Kerr et al., 2019).

How different are the fermentation processes in different types of beers? How important are they to the differences between the different types of beers?

There are generally two fermentation types:

1) Ale fermentation or top-fermenting: which uses strains of Saccharomyces cerevisiae and fermentation occurs at ~22 C.

2) Lager fermentation or bottom-fermenting: which uses strains of Saccharomyces pastorianus and fermentation occurs at colder temperatures.

Other than this, there are strains and species of yeast from the environment (A.K.A, wild yeast) or other types of yeast, that can be used to spontaneously ferment that do not follow this Ale/Lager fermentation system.

Study of S. pastorianus genome has revealed that this organism is a domesticated hybrid strain of S. eubayanus and S. cerevisiae (Libkind et al., 2011). Different to its wild ancestor, S. pastorianus gain the ability from S. cerevisiae to process disaccharide maltose which is highly abundant in wort (Libkind et al., 2011).

Between different beers, people used to say that water is a differentiating factor in beer brewing, in modern beer production, it is actually the element that introduces the least variability to the process, due to the usage of purified water in modern beer brewing with minerals being add at a later stage and other chemical elements. Commercial yeasts that are in use, are often produced by the same company. This practice does not provide with enough variability to the brewing processes of different beer types. It is often the malt, which can vary a lot between regions as well as the production process, that makes the difference between different beers. Currently, in the lab, there is a study looking at the difference in soluble protein content within the malt and yeast, comparing them between brewing styles, breweries, and regions.

From the analysis of your proteomics data, what potential impact do you think it can have on beer production? Have any of your discoveries led to any changes in your fermentation process?

Proteomics specifically has not led to any direct changes in the brewing process. We are working on using proteomics to gain and improve screening for new barley varieties for brewing that are disease resistant and higher quality.

Besides different yeast strains giving different flavoring compounds as well as alcohol content, different barley varieties would also have different amounts of available sugars in wort for fermentation as well as flavor compounds. The usage of different varieties could also offer higher or lower level of alcohol and different flavor profiles.

What are the different beers that you are currently working with? How different are they from the production and proteomics perspective?

We are working on wild yeast, which typically are not used by commercial breweries. Fermenting with these yeasts is difficult and poorly understood. We have had great difficulties taking yeast and upscaling the production from a small 30 mL scale in a lab to 1000 L in a brewery.

We haven’t used proteomics yet to help with these industrial challenges but it is on our list!

The current brewing process has been highly optimized for the use of traditional brewer’s yeast. Similar to what we have discussed above, different brewing yeasts would ferment optimally at different temperatures. Wild yeast suppose a different challenge, partly because they are not well understood and have not been characterized. They might require a different configuration entirely for scalability to be effective in an industrial setting.

What results have you achieved with them so far?

We are getting close to being able to produce commercial batches of our yeast with our industry partner Newstead Brewing Co., but further from these using proteomics and microbiology we have really gained an understanding of the entire brewing process using new modern biochemical techniques that are not applied to this field as of yet.

What do you think is the most interesting aspect of modern beer production?

Definitely the people. Everyone in craft/independent brewing are helpful, lovely, and genuinely interested in brewing beer and providing a unique and interesting beer.

Brisbane, Queensland, Australia – 25th, November, 2019

Bibliography

Curry, Andrew. (2017, January 17). Our 9,000-Year Love Affair With Booze. Retrieved December 13, 2019, from National Geographic website: https://www.nationalgeographic.com/magazine/2017/02/alcohol-discovery-addiction-booze-human-culture/

Kerr, E. D., Caboche, C. H., & Schulz, B. L. (2019). Post-translational modifications drive protein stability to control the dynamic beer brewing proteome. Molecular & Cellular Proteomics, mcp.RA119.001526. https://doi.org/10.1074/mcp.RA119.001526

Libkind, D., Hittinger, C. T., Valério, E., Gonçalves, C., Dover, J., Johnston, M., … Sampaio, J. P. (2011). Microbe domestication and the identification of the wild genetic stock of lager-brewing yeast. Proceedings of the National Academy of Sciences, 108(35), 14539. https://doi.org/10.1073/pnas.1105430108

Meyen, F. J. F. (1839). Jahresbericht über die Resultate der Arbeiten im Felde der physiologischen Botanik von dem Jahre 1837. Nicolai.

Stewart, G. G. (2017). History of Brewing and Distilling Yeast. In G. G. Stewart (Ed.), Brewing and Distilling Yeasts (pp. 11–36). https://doi.org/10.1007/978-3-319-69126-8_2

Willaert, R. (2006). The Beer Brewing Process: Wort Production and Beer Fermentation. In Handbook of Food Products Manufacturing (pp. 443–506). https://doi.org/10.1002/9780470113554.ch20

1 thought on “Food Science Series: Beer Science”